Have you ever wondered why compressed air seems to burn a hole in your wallet? You’re not alone.

Many people are shocked to discover how expensive compressed air can be. It’s a resource that’s crucial for countless industries and everyday applications, yet its cost often comes as a surprise. Imagine if you could unlock the secrets behind these high costs and potentially save money for your business or personal projects.

Wouldn’t you want to know more? We’ll dive into the reasons compressed air is so pricey, shedding light on the hidden factors that drive up its cost. By understanding these, you might just find ways to make more economical choices and optimize your expenses. Keep reading to uncover the truth about why your air supply might be costing you more than you think.

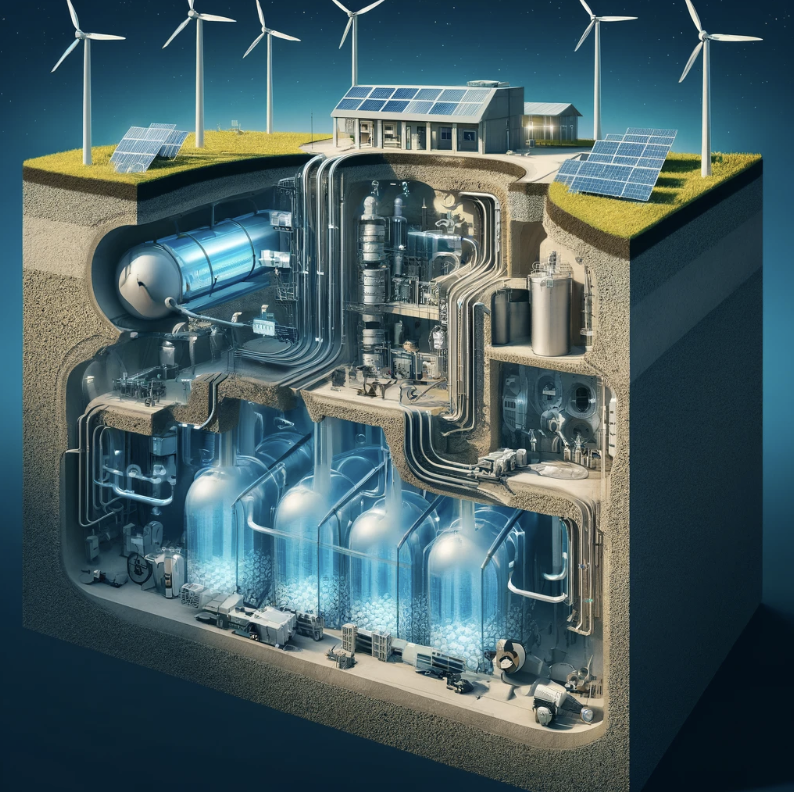

Credit: infinityturbine.com

The Basics Of Compressed Air Systems

Compressed air systems might seem simple, but their complexity and importance can surprise you. These systems are more than just machines that pump air; they are intricate networks designed to perform critical tasks across various industries. Understanding the components and functionality of compressed air systems can help you appreciate why they come with a hefty price tag.

Components And Functionality

Compressed air systems consist of several key components: compressors, air tanks, filters, dryers, and distribution lines. The compressor is the heart of the system, generating pressurized air that is stored in tanks and distributed to different parts of your operation. Each part plays a crucial role in ensuring efficiency and reliability.

Think about the compressor as the engine of a car. Just like how a well-maintained engine ensures smooth rides, a high-quality compressor guarantees consistent air pressure. Regular maintenance of filters and dryers keeps the air clean and dry, preventing damage and downtime.

Have you ever had a day ruined by a flat tire or a car breakdown? Imagine that happening to your business because of neglected air system components. It’s a high cost, not just financially, but also in productivity.

Common Applications

Compressed air is essential in various industries, from manufacturing to healthcare. In factories, it powers pneumatic tools and controls automation systems. In hospitals, it ensures the operation of critical equipment like ventilators.

Consider a woodworking shop; compressed air not only powers drills and saws but also keeps dust at bay, enhancing safety and precision. Without it, the shop’s efficiency drops dramatically, impacting both output and quality.

Do you use compressed air at home, perhaps for inflating tires or cleaning? Even in simple tasks, you can feel its value. Imagine scaling that up to industrial levels, where reliability and performance are non-negotiable.

As you ponder the cost of compressed air, ask yourself: What price would you put on efficiency, safety, and reliability? The next time you see a hefty bill for air systems, consider the unseen benefits and savings it brings to your operation.

Initial Investment Costs

Compressed air involves high initial investment costs due to specialized equipment and installation. Energy consumption adds to expenses, making it costly. Maintenance and repairs further increase the overall price of compressed air systems.

Understanding why compressed air is so expensive often starts with the initial investment costs. Many are surprised by the upfront expenses associated with setting up a compressed air system. These initial costs can be a real eye-opener, especially if you’re new to the world of industrial equipment. Let’s dive into some key components that contribute to these costs.Equipment And Installation

Purchasing the right air compressor is just the tip of the iceberg. High-quality compressors can range from a few thousand to several hundred thousand dollars, depending on capacity and features. Add to that the installation costs, which can include hiring specialized technicians and ensuring compliance with safety standards.Installation isn’t just a matter of plugging in a machine. It involves setting up the compressor, securing it in place, and making sure all connections are airtight. Have you considered the cost of downtime during installation? If your business relies on compressed air, any downtime can be costly.Infrastructure Requirements

Installing a compressed air system often requires significant changes to your existing infrastructure. This might mean new piping, additional electrical circuits, or even structural modifications to support heavy equipment. Each of these changes comes with its own set of costs.Consider the space needed for the compressor and related equipment. Do you have sufficient room, or will you need to expand? The cost of expanding or modifying your facility can add up quickly. How about ventilation and cooling systems? These are vital to ensure your compressor operates efficiently and safely.When I first set up my workshop, I underestimated the infrastructure needs. The costs of unexpected modifications quickly spiraled, teaching me the importance of thorough planning. Have you fully assessed what your space will need?These initial investment costs may seem daunting, but understanding them is crucial. By planning carefully and considering all aspects, you can manage these expenses more effectively. What steps will you take to ensure your investment is a smart one?Energy Consumption Factors

Compressed air is expensive due to its high energy consumption. Producing compressed air requires substantial electricity, often resulting in inefficiencies. These inefficiencies lead to increased costs, making it crucial to optimize systems for better energy management.

Compressed air is a vital resource for many industries. Its production costs can be surprisingly high. One significant factor is energy consumption. Understanding these factors can help manage costs effectively.Efficiency Challenges

Compressors often operate with low efficiency. This inefficiency increases energy use. Over time, even small inefficiencies add up. Regular maintenance can help, but it often gets overlooked. A well-maintained system runs smoother and saves energy.Power Demands

Producing compressed air requires significant power. Compressors need a lot of electricity to function. This demand drives up costs. The more power a compressor needs, the more expensive the operation. Choosing the right compressor size can help manage power needs effectively.Maintenance And Repair Expenses

Compressed air incurs high costs due to maintenance and repair expenses. Regular upkeep is essential to ensure efficient operation. Equipment wear and tear can lead to increased energy consumption. This adds to overall expenses.

Compressed air is often seen as a hidden cost in many industries. While it may seem like a simple solution for powering tools and machines, maintaining and repairing the systems that produce compressed air can be surprisingly expensive. Understanding these costs is essential for businesses looking to manage their budgets effectively.Routine Servicing

Regular maintenance is crucial for the smooth operation of any compressed air system. Just like your car needs an oil change, compressors require routine servicing. This can include changing filters, checking for leaks, and ensuring that the system is running efficiently.Neglecting these routine checks can lead to bigger problems down the line. Imagine skipping your car’s service appointments and then facing a breakdown. The same principle applies to compressed air systems; skipping maintenance can lead to costly repairs.To keep costs down, create a maintenance schedule and stick to it. Regular servicing not only extends the life of your equipment but also helps in avoiding unexpected expenses. It’s a small price to pay for peace of mind and a well-functioning system.Unexpected Breakdowns

Even with the best maintenance practices, unexpected breakdowns can still occur. These can disrupt your operations and lead to significant downtime. Have you ever been caught off guard by a sudden equipment failure? It’s not just frustrating—it’s costly.When a compressed air system fails, you might find yourself scrambling to find a technician and spare parts. The urgency can inflate costs, as repairs often need to be done quickly to minimize impact on production. Planning for these scenarios can save you money and stress.Consider setting aside a budget for emergency repairs. This foresight ensures you’re prepared for unexpected breakdowns, reducing their financial impact. Being proactive rather than reactive can make a significant difference in managing your compressed air expenses.Understanding the costs associated with maintaining and repairing compressed air systems can help you make smarter decisions for your business. Are your maintenance practices keeping your system in top shape, or are you leaving room for costly surprises?Operational Inefficiencies

Compressed air systems are essential in many industries. Yet, they often face operational inefficiencies that drive costs up. High energy expenses plague these systems, impacting their overall performance. Understanding these inefficiencies can help manage and reduce costs effectively. Let’s explore key issues that contribute to this problem.

Leakage Issues

Leakage is a significant problem in compressed air systems. Tiny cracks and holes in pipes can lead to substantial air loss. This loss forces systems to work harder, using more energy. Regular maintenance checks are crucial. They help identify and fix leaks promptly. Ignoring leaks can lead to increased operating costs. Efficient sealing of leaks can save money and energy.

Pressure Drop

Pressure drop occurs when air loses force as it travels through the system. It results from friction in pipes, fittings, and filters. This drop causes systems to consume more energy to maintain required pressure levels. Proper system design can minimize pressure drops. Using appropriate pipe sizes and reducing bends can help. Regular inspection ensures optimal performance and energy efficiency.

Environmental And Regulatory Costs

Compressed air is often more expensive than you might expect. A significant chunk of this cost stems from environmental and regulatory requirements. These aren’t just arbitrary rules; they are essential for safeguarding our planet and ensuring that air compression processes are safe and sustainable. However, meeting these standards often requires substantial investment, which drives up costs. Have you ever wondered how these regulations specifically impact the bottom line of compressed air production?

Emission Standards

Emission standards are critical in the compressed air industry. They dictate the allowable levels of pollutants released during production. These standards are necessary to minimize environmental harm but adhering to them can be costly. This often involves upgrading equipment or implementing new technologies to reduce emissions.

Think about the last time a piece of equipment broke down. Now imagine needing to replace it with a more eco-friendly version. It’s not just about the initial purchase; it’s also about the ongoing maintenance and operational changes. Meeting emission standards isn’t a one-time effort; it’s a continuous commitment to environmental responsibility.

Compliance Costs

Compliance costs can add up quickly. Companies must invest in monitoring systems, regular inspections, and staff training to ensure they meet regulatory requirements. These expenses are necessary for avoiding fines and maintaining operations but can be hefty.

Consider the complexity of keeping up with changing regulations. It’s like playing a game where the rules change frequently, requiring constant vigilance. How do you keep your team informed and your systems updated without breaking the bank? This is a real challenge for businesses in the compressed air industry.

It’s crucial to weigh these costs against the benefits of compliance. While they may seem burdensome, they ultimately contribute to a safer and cleaner environment. What’s your perspective on balancing cost with sustainability? Could there be more innovative ways to manage these expenses?

Technological Innovations

Compressed air is costly due to high energy use in production. Maintenance and equipment expenses add to the price. Efficient use and regular checks can help manage costs.

Compressed air might seem like a simple utility, but the technology behind it is anything but straightforward. The high costs often associated with compressed air systems are largely due to the cutting-edge innovations that have transformed how these systems operate. Let’s delve into some of these technological advancements and see how they contribute to the hefty price tag of compressed air.Energy-saving Technologies

Modern compressed air systems boast energy-saving technologies that significantly reduce electricity consumption. Variable speed drives (VSDs) adjust the motor speed to match the demand, minimizing wasted energy. These systems can be a game-changer in reducing your energy bills, but they come at an initial cost.Think about how much energy your household appliances use. Now, imagine if each one had a feature to use only the energy required at any given moment. Compressed air systems with VSDs do just that, making them efficient but more expensive.Have you ever considered how a small change in energy use could impact your budget? These advanced technologies do just that, offering savings over time but at a price.Smart Systems

Smart systems in compressed air technology offer real-time data and diagnostics. They monitor the performance, detect leaks, and predict maintenance needs before a breakdown occurs. This proactive approach prevents costly downtime and improves system reliability.Consider how a smartphone app helps you track your fitness goals. Similarly, smart systems provide insights into your air system’s health, leading to better management and cost savings.The integration of smart systems can feel like having an expert on standby, ensuring everything runs smoothly. However, this convenience and efficiency come with a higher upfront investment.Are you leveraging technology to its fullest potential in your daily life? In the world of compressed air, smart systems do just that, enhancing efficiency while adding to the overall cost.These technological innovations, while expensive, offer long-term savings and operational efficiency. Would you prefer to pay more upfront for efficiency or deal with higher energy costs and maintenance later?

Credit: sdtultrasound.com

Cost Reduction Strategies

Compressed air can be surprisingly costly for businesses. Many find themselves facing high energy bills. The expenses can seem overwhelming. This is why cost reduction strategies are crucial. These strategies aim to reduce expenses while maintaining efficiency. Implementing smart approaches can help save money. Below are some effective strategies for reducing costs.

Efficient System Design

Designing an efficient system is key to lowering costs. This involves using the right equipment. Choose tools that consume less energy. Proper sizing is important too. Oversized systems waste energy and money. Smart design reduces the need for frequent maintenance. It also minimizes downtime. Ensure the layout allows smooth air flow. This avoids unnecessary pressure drops. An efficient design reduces operating costs significantly.

Regular Audits

Conducting regular audits helps identify inefficiencies. These audits reveal leaks and other issues. Fixing leaks can save a lot of money. Audits help check system performance. They ensure equipment runs at optimal levels. Routine checks prevent unexpected breakdowns. They also extend equipment life. Audits keep everything running smoothly. Regular assessments are essential for cost management. They help maintain a balanced budget.

Credit: westairgases.com

Frequently Asked Questions

Why Is Compressed Air So Costly?

Compressed air systems need much energy. Maintenance and equipment costs add to the expense.

How Can Businesses Reduce Compressed Air Costs?

Fix leaks. Use efficient compressors. Regular maintenance helps. Optimize system design.

What Factors Increase Compressed Air Prices?

Energy consumption is high. Equipment and installation costs add up. Maintenance needs are frequent.

Is Compressed Air More Expensive Than Electricity?

Yes, compressed air is often pricier. Its production requires much more energy than electricity.

Can Compressed Air Systems Be Energy Efficient?

Yes. Use energy-saving compressors. Regularly check for leaks. Proper system design can help reduce costs.

Conclusion

Compressed air costs can surprise many businesses. Equipment, maintenance, and energy all add up. Each component plays a crucial role. Understanding these factors helps in budgeting effectively. Reducing waste and optimizing usage can lower expenses. Regular checks prevent costly repairs and inefficiencies.

Businesses must plan and monitor their air systems. Educating staff about air usage can also make a difference. Small changes contribute to significant savings over time. Adopting energy-efficient practices benefits both the budget and the environment. With informed decisions, businesses can manage costs better.

Always keep an eye on the air compressor system. It pays off in the long run.