Choosing the right insulation for your air conditioning pipes can be a daunting task. With so many options out there, how do you know what’s best for your home or office?

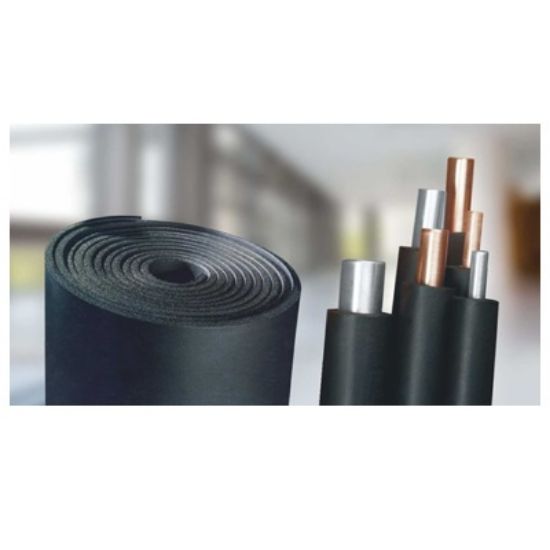

You’ve likely come across two popular choices: foam and rubber. Each has its own strengths and weaknesses. But which one truly meets your needs? We will delve into the world of AC pipe insulation, comparing foam and rubber to help you make an informed decision.

Imagine saving on energy bills, extending the life of your AC system, and enhancing comfort in your space. Intrigued? Let’s explore the battle of foam vs. Rubber and discover which one is the perfect fit for you. Keep reading to uncover the secrets that could transform your cooling system today.

Material Composition

Choosing between AC pipe insulation foam and rubber depends on specific needs. Foam offers lightweight and easy installation, while rubber provides durability and flexibility. Each material has unique benefits, making them suitable for different applications.

Choosing the right material for your AC pipe insulation can make a significant difference in the performance and energy efficiency of your cooling system. Material composition is a key factor to consider when you’re deciding between foam and rubber insulation. Each material has its unique properties that can impact your decision. You might have a memory of a summer when your AC struggled to keep your home cool. Understanding the composition of these materials can help you prevent that situation from happening again.###Properties Of Foam

Foam insulation, often made from polyethylene or polyurethane, is known for its lightweight and flexible nature. It’s easy to install, making it a favorite among DIY enthusiasts.Foam offers excellent thermal resistance, helping to keep the cold air in and the hot air out. This can lead to reduced energy bills and a more comfortable home environment.However, foam is susceptible to UV damage, which can degrade its effectiveness over time. If your pipes are exposed to sunlight, you might want to consider additional protective measures.###Properties Of Rubber

Rubber insulation, typically made from synthetic materials like EPDM, is celebrated for its durability and resilience. It’s known to withstand extreme temperatures, making it suitable for various climates.Rubber is resistant to moisture and UV rays, which means it can hold up well over time even when exposed to the elements. This can save you the hassle of frequent replacements.On the flip side, rubber can be a bit heavier and more challenging to install compared to foam. It might require a professional touch to ensure it’s applied correctly.Have you ever wondered why your AC bills skyrocket in the summer? The choice between foam and rubber could be the game changer you need. Which material aligns best with your needs?

Credit: www.thesmarthvac.com

Thermal Insulation Performance

Thermal insulation performance is crucial for maintaining indoor comfort. It reduces energy consumption in HVAC systems. Ac pipe insulation foam and rubber are popular choices. Both materials offer distinct advantages and limitations. Understanding their thermal insulation performance helps in making informed decisions.

Effectiveness In Different Climates

Foam insulation adapts well to moderate climates. It provides consistent insulation. In extreme temperatures, its effectiveness may vary. Rubber insulation excels in diverse climates. It maintains performance in hot and cold conditions. Its flexibility ensures a tight seal around pipes. This reduces heat loss and prevents condensation.

Energy Efficiency Comparison

Foam insulation offers good energy efficiency. Its lightweight nature aids in quick installation. It minimizes energy loss, reducing HVAC load. Rubber insulation stands out with superior energy efficiency. Its dense structure provides excellent thermal resistance. This results in lower energy bills and enhanced system performance.

Durability And Longevity

Choosing the right insulation for AC pipes involves considering durability and longevity. These factors determine how well the insulation performs over time. Foam and rubber insulation are two popular choices. Each has unique qualities affecting their durability.

Resistance To Wear And Tear

Foam insulation offers a smooth surface, reducing friction wear. It is less prone to scratches and dents compared to rubber. Over time, rubber can show signs of wear in high-traffic areas. Foam maintains its integrity longer in such conditions.

Impact Of Environmental Factors

Environmental conditions greatly affect insulation performance. Foam is susceptible to UV rays, which can cause degradation. It is crucial to protect foam from direct sunlight. Rubber, on the other hand, is UV resistant. It holds up better under sun exposure.

Both foam and rubber can handle moisture well. Yet, rubber boasts better resistance to extreme temperatures. Foam might shrink or expand with temperature changes. Rubber remains stable, ensuring consistent insulation.

Ease Of Installation

Choosing the right insulation for your AC pipes can be a game-changer in efficiency and comfort. Ease of installation is a critical factor that can save you time and effort. Whether you’re a seasoned DIY enthusiast or just starting out, understanding the installation process for foam and rubber insulation will guide you in making an informed decision.

Installation Process For Foam

Foam insulation is known for its simplicity and user-friendly nature. It’s lightweight and easy to cut, making it a favorite for quick installs. You simply need a sharp knife or scissors to adjust the size to fit around your pipes.

Once cut, foam insulation typically comes with a self-adhesive strip, which makes it easy to secure. You wrap it around the pipe and press it down firmly to ensure a snug fit. It’s a straightforward process that requires minimal tools and effort.

While installing foam, pay attention to the ends and joints. Properly sealing these areas prevents air leakage and maximizes efficiency. Have you ever felt frustrated by complex instructions? Foam insulation offers relief with its straightforward application.

Installation Process For Rubber

Rubber insulation is slightly more challenging but offers excellent durability. It’s heavier and requires more effort to cut, often needing a utility knife. This might be a task requiring a bit more patience.

Unlike foam, rubber insulation often lacks a self-adhesive strip. You’ll need to use adhesive or tape to secure it around your pipes. This adds a step but allows for a more customizable fit.

Rubber insulation shines in flexibility. It easily bends around curves and corners, making it ideal for complex pipe networks. Do you have pipes with multiple bends? Rubber might be your go-to for a tailored fit.

Choosing between foam and rubber insulation comes down to your specific needs and preferences. What’s more important to you: ease of use or durability? Each option offers unique benefits that cater to different situations. Your decision can impact not only the ease of installation but also the longevity and efficiency of your AC system.

Cost Analysis

When deciding between AC pipe insulation foam and rubber, understanding the cost implications is crucial. Both materials come with distinct financial considerations that can impact your budget today and in the future. Let’s dive into the cost analysis of these two options.

Initial Costs

Choosing AC pipe insulation foam typically means lower upfront expenses. Foam is generally cheaper to produce, which translates into a lower price point for you. If you’re working on a tight budget, foam might seem like the obvious choice.

Rubber, on the other hand, tends to be more expensive initially. But why? The cost is often justified by its superior durability and flexibility. This could be crucial if you’re insulating pipes in areas with fluctuating temperatures or tight spaces.

Long-term Maintenance Costs

Foam insulation might save you money initially, but it can require more upkeep. Over time, foam can degrade, especially in high moisture environments. This means you might end up spending more on repairs or replacements.

Rubber insulation, despite its higher initial cost, often stands the test of time better. Its resistance to moisture and temperature changes means fewer repairs and replacements down the line. Could investing more upfront save you money in the long run?

In my own experience, opting for rubber insulation in a damp basement proved worthwhile. Though the initial expenditure was steep, the reduced maintenance hassle was a relief.

As you weigh your options, consider not only today’s budget but also future expenses. Are you prepared for potential maintenance costs with foam? Or would you prefer the durability of rubber? Making the right choice could save you headaches and money. Which route will you take?

Credit: www.stringssg.com

Environmental Considerations

Choosing between AC pipe insulation foam and rubber has environmental impacts. Each material affects the environment differently. Understanding these impacts helps you make an informed decision.

Eco-friendliness

AC pipe insulation foam is usually made from synthetic materials. These materials often rely on petrochemicals. This reliance can harm the environment. Rubber insulation, on the other hand, often comes from natural sources. It can be more eco-friendly. Natural rubber production supports sustainable practices.

Recyclability

Recyclability is a major factor in environmental impact. Foam insulation can be challenging to recycle. It often ends up in landfills. Rubber insulation offers better recyclability. Many facilities can process old rubber. This reduces waste and supports a circular economy.

Safety And Health Impacts

Choosing the right insulation for your AC pipes is crucial. Safety and health impacts play a significant role in this decision. Foam and rubber insulations differ in these aspects. Understanding these differences can help make an informed choice.

Potential Health Risks

Foam insulation may contain chemicals. Over time, these can release into the air. This may cause allergies or irritation for some individuals.

Rubber insulation has fewer chemical concerns. It is generally considered safer for indoor air quality. This makes it a preferred choice for health-conscious homeowners.

Fire Safety

Foam insulation can be flammable. In case of a fire, it may release harmful gases. This poses a risk to both health and safety.

Rubber insulation is often more fire-resistant. It can withstand higher temperatures without igniting. This makes it a safer option for fire-prone areas.

User Reviews And Feedback

Deciding between foam and rubber insulation for your AC pipes can be challenging. User reviews and feedback offer valuable insights into real-world experiences with these materials. Understanding what others have faced can help you make a more informed decision for your insulation needs.

Foam User Experiences

Many users appreciate the lightweight nature of foam insulation. It’s easy to handle and install, making it a favorite for DIY enthusiasts.

One user shared how foam insulation helped reduce energy bills significantly. The material’s insulating properties kept their indoor environment stable, preventing unnecessary heat loss.

However, some users noted its vulnerability to damage. Foam can tear easily, especially during installation, which might lead to frequent replacements.

Is foam’s ease of use worth the potential for wear and tear? Consider how often you’ll need to replace it.

Rubber User Experiences

Rubber insulation often receives praise for its durability. Users find it more resistant to physical damage compared to foam.

Several reviews highlight rubber’s excellent performance in extreme temperatures, maintaining its insulating properties without deteriorating.

On the downside, some users mention its weight and higher cost. It’s heavier and can be more challenging to install without professional help.

Does the robustness of rubber justify the extra effort and cost? Weigh the pros and cons based on your situation.

User feedback suggests both materials have their strengths and weaknesses. Think about your priorities: ease of installation or long-term durability? Your choice could make a significant difference in how effectively your AC system operates.

Final Recommendation

Choosing between foam and rubber for AC pipe insulation depends on specific needs. Foam offers better thermal insulation, while rubber excels in flexibility and moisture resistance. Both materials have unique advantages, making the decision based on environmental conditions and installation preferences crucial.

Choosing between AC pipe insulation foam and rubber can be challenging, especially with so many factors to consider. Both materials offer unique benefits, and your decision should align with your specific needs. Let’s break it down to find out which is best for residential and commercial uses.Best Choice For Residential Use

For your home, pipe insulation foam often stands out. It’s affordable, easy to install, and offers good thermal protection. Imagine you’re tackling a DIY project over the weekend; the lightweight nature of foam makes it a breeze to handle.Foam is also resistant to mold and mildew, making it an excellent choice for areas with high humidity. If you value a clean, hassle-free solution, foam might just be your go-to. Does the idea of a cozy, energy-efficient home appeal to you?Best Choice For Commercial Use

In a commercial setting, rubber insulation often proves superior. It offers exceptional durability and flexibility, which is critical in high-traffic areas. Consider the hustle and bustle of a busy office or factory—rubber can withstand the demands.Rubber is also more resistant to physical damage and chemical exposure, ensuring longevity. If you’re managing a large facility, the peace of mind that comes with rubber’s robust nature could be invaluable. Are you ready to invest in something that stands the test of time?Ultimately, your choice depends on the environment and specific needs. Foam is ideal for residential spaces with its cost-effectiveness and ease of use. Rubber, with its durability and versatility, suits commercial settings well. Which material aligns best with your situation?

Credit: www.hvacfoam.com

Frequently Asked Questions

What Are The Benefits Of Foam Insulation For Ac Pipes?

Foam insulation is lightweight and easy to install. It provides good thermal resistance, helping to reduce energy loss.

How Does Rubber Insulation Differ From Foam?

Rubber insulation is durable and flexible. It resists moisture and can handle varying temperatures better than foam.

Which Insulation Type Is More Cost-effective?

Foam insulation is generally cheaper. Rubber insulation can be more expensive due to its durability and flexibility.

Can Rubber Insulation Improve Energy Efficiency?

Yes, rubber insulation offers superior thermal resistance. It helps maintain temperature, reducing energy consumption in AC systems.

Is Foam Insulation Suitable For Outdoor Use?

Foam insulation is not ideal for outdoor use. It can degrade in sunlight and harsh weather conditions.

Conclusion

Choosing between foam and rubber insulation depends on your needs. Foam offers better thermal efficiency. It’s lightweight and easy to install. Rubber is more durable and resists moisture well. Great for outdoor use. Both materials have unique benefits. Consider your climate and budget.

Foam is often cheaper. Rubber lasts longer in harsh conditions. Evaluate your AC setup carefully. Select insulation that best protects your system. A wise choice improves efficiency and reduces energy costs. Both options serve well. Just pick what suits your situation best.

Stay comfortable and save money with the right insulation.